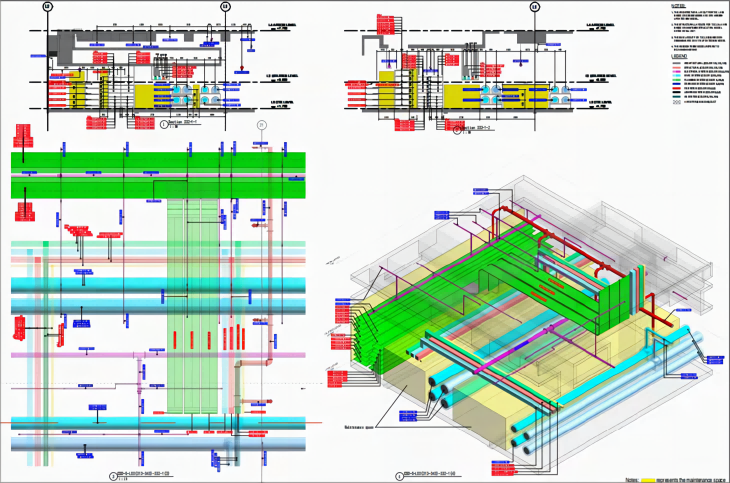

·The Horry DfMA design team will proactively compile a state of the art analysis of the piping layout sections for each area based on the process version of the E&M piping synthesis model.

·The Horry DfMA design team will proactively compile a collision group inspection report for each area based on the process version of the integrated electrical and mechanical pipeline model.

·The Horry DfMA design team will proactively build a baseline model of the E&M piping supports in each area based on the process version of the E&M piping synthesis model.

·The Horry DfMA design team will proactively produce zone headroom maps and E&M depth maps based on the process version of the integrated E&M pipeline model.

·The Horry DfMA design team will proactively follow the process version of the E&M piping integrated model, build module occupancy models and fill in various reference models, such as inspection space, light boxes, signage steel frames, smoke roller shutters and so on.